A Swiss-type CNC machine is a type of turning center that was developed for the Swiss watch industry. These machines are designed to turn small, complex, precision parts and mill them with accuracy and consistency. Due to this capability, this type of milling machine is used to achieve the strict dimension and tolerance requirements necessary for application in the aerospace, military and medical industries.

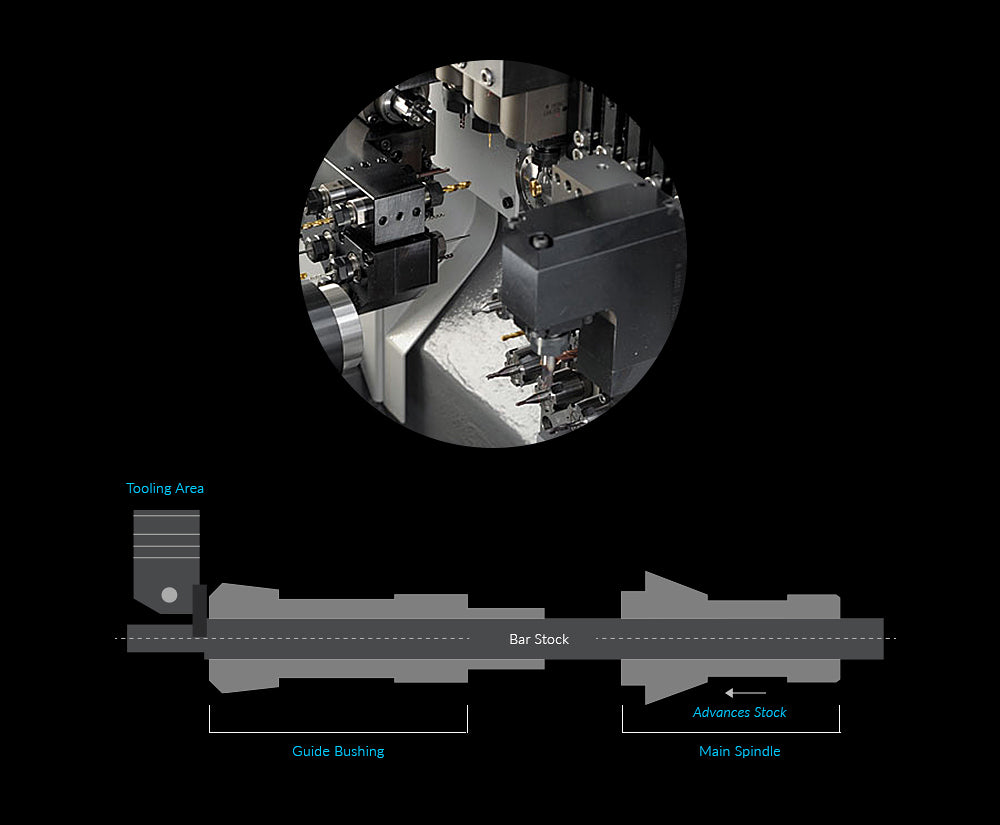

What distinguishes a Swiss machine from other types is that its headstock moves. Unlike conventional machines where the part is stationary and the tool moves, a Swiss-type turning center allows the part to move in the Z axis and the tool is stationary. It allows the bar to emerge into the tooling area through a guide bushing, which locates the bar radially during machining. The headstock moves precisely back and forth in the z-direction, taking the bar with it.

The guide bushing is the “heart” of Swiss machining. A physical object subjected to a force will deflect. But with a Swiss machine, the guide bushing supports the workpiece so close to the tools that the deflection due to the cutting forces is essentially zero thus increasing accuracy and consistency.